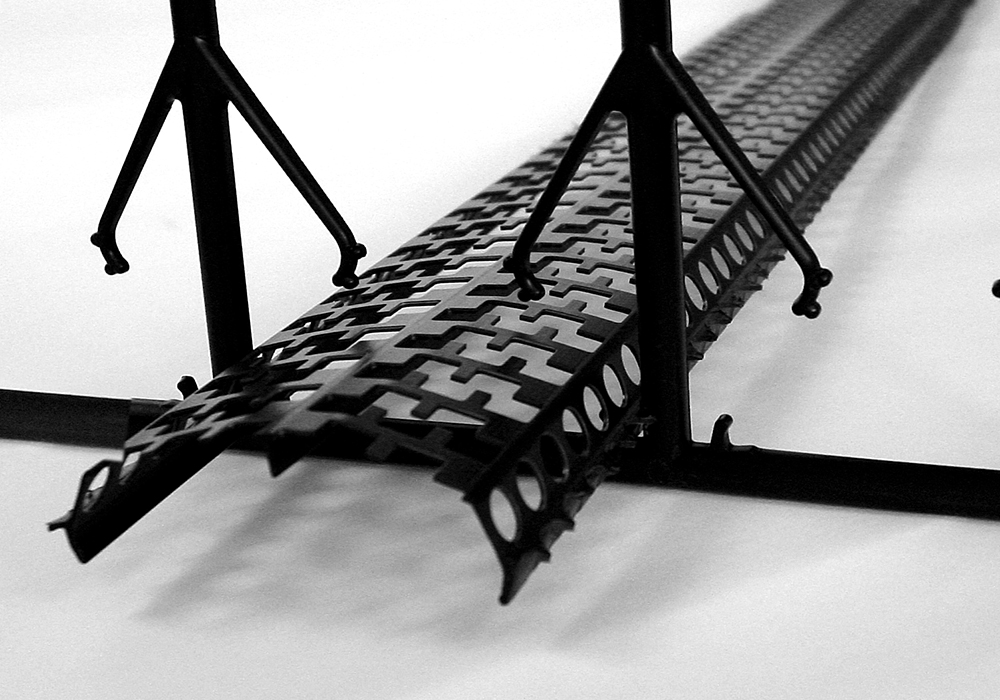

Marley® Crossflow Splash Fill

Thermal Performance

Replacing Mesa fill with Gull Wing fill can reduce thermal performance up to 13% resulting in a higher cold water temperature exiting the cooling tower.*

Energy Savings

The lower thermal performance of competitive fills may require an increase in fan power consumption to achieve equivalent heat rejection.

Durability

Each Mesa bar is firmly attached to the Marley GridLoc™ support structure, providing a strong and nonabrasive support that eliminates the need for potentially abrasive bench supports.

Certification

Meets or exceeds CTI Standard 136 for strength, flammability, and impact testing.

Flame Spread

Constructed of PVC, Mesa fill has a low flammability risk compared to competitive fills made with polypropylene.

Product Design Knowledge

The PVC formulation used by Marley fill has been specially formulated, tested, and proven to prevent degradation in the harsh conditions of cooling towers.** For example, strong impact modifiers are used to prevent damage from UV light.

Innovation

SPX is dedicated to continuously improve its fill products and currently has 23 fill patents.

*Based on case study calculating the approach temperature at the SPX CT Development Center, using 4” Gull Wing bar, 8” V x 8”H staggered, parallel flow, for the following tower configuration and process conditions: – Tower Configuration: 10-cell Crossflow Tower located in the Gulf Coast United States – Water Flow Rate: 16,000 GPM per cell – Thermal Conditions: 107.3/90/78 degrees F for Hot Water, Web Bulb, and Cold Water Temperatures

**Based on Exposure and Load Testing conducted at the SPX CT Development Center

Head-to-Head Comparison

| MARLEY Mesa | C.E. Shepherd Gull Wing | |

|---|---|---|

| For Marley towers originally built with Mesa, replacement with Mesa will deliver thermal performance equivalent to original OEM design | Thermal Performance | Case studies show that replacement with Gull Wing fill can reduce tower performance up to 13% compared to Marley Mesa, resulting in a higher cold water temperature* |

| Greater thermal performance of fill translates directly into lower energy consumption by the motor | Energy Savings | Gull Wing fill can result in an increase in annual energy costs up to $6,079 per cell compared to Marley Mesa fill due to increased power consumption to maintain the same cold water temperature** |

| Each bar is firmly attached to the Marley GridLoc injection-molded support, providing a nonabrasive support that eliminates the need for bench supports or connector clips | DURABILITY | Plastic clips are required to secure bars to the grid, which may not entirely eliminate movement between bar and grid. Over time, due to the stress of falling water, abrasion may occur, further loosening the structure and may create an unstable fill assembly In addition, the connector clips may become disconnected and fall into the return water stream |

| The flame spread index (FSI) for Mesa is 15 or less, demonstrative of the “low flammability risk for PVC” as stated in CTI STD-136 specification | FLAME SPREAD INDEX | No published data obtainable |

|

Reference: |

||

| * | Based on case study calculating the approach temperature at the SPX CT Development Center, using 4” Gull Wing bar, 8”V x 8”H staggered, parallel flow, for the following tower configuration and process conditions: – Tower Configuration: 10-cell Crossflow Tower located in the Gulf Coast United States – Water Flow Rate: 16,000 GPM per cell – Thermal Conditions: 107.3/90/78 degrees F for Hot Water, Web Bulb, and Cold Water Temperatures | |

| ** | Additional BHP is required to maintain the design exit cold water temperature. The resulting energy cost increase can be calculated as follows: – Tower Configuration: Same as shown above.* – Motor Design hp: 144.5 hp – Motor hp required to maintain cold water temperature after 13% loss in thermal performance: 153.8 hp (9.3 additional hp) – 9.3 hp = 6.9 kW – 6.9 kW X 8,760 hours per year = 60,794 kW per year – Use average price of electricity in your region to calculate cost per year http://www.eia.gov/electricity/monthly/epm_table_grapher.cfm?t=epmt_5_6_b – Assuming cost of $0.10 per kW hour: – Cost = 60,794 x $0.10 = $6,079 annual cost increase, per cell, to maintain cold water exit temperature equivalent to Marley Mesa Fill |