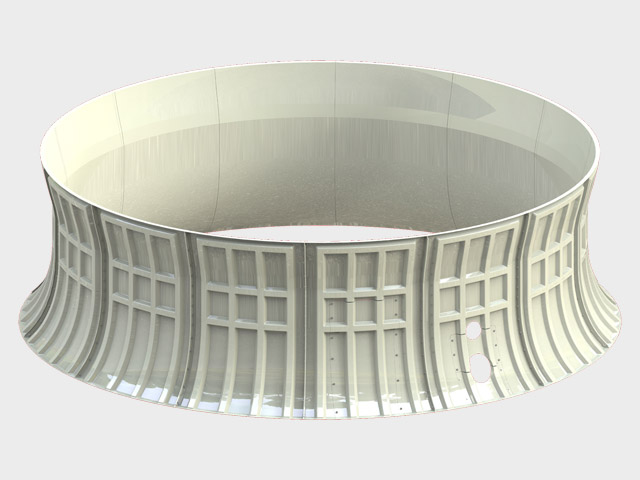

Marley® Reflex 10′ Fan Cylinders

Performance: Marley Reflex Fan Cylinders Perform up to 1.7% better in CFM than others to increase cooling tower capacity or require up to 5% less power to deliver equivalent CFM, which can result in up to $6,535 in annual energy cost reduction.

Strength: Butt flange design requires fewer components to meet industry standards. Deep section vertical and horizontal ribs provide strength against wind load deflection and resistance to vibration.

No Hardware in Airstream: All hardware connections are outside the cylinder which eliminate concern for fan interference.

Low Profile: Marley Reflex design allows our 10’ tall cylinders to perform equal to other fan cylinder offerings in the market that are 14’ tall, while offering higher wind load capability and less stress on cooling tower structural frame. Shorter segments also translate to easier handling at jobsite without need for special equipment.

Ease of Assembly: All segment connection hardware can be accessed from fan cylinder exterior due to butt flange design.

Large Access Door: Marley Reflex access door is 75” tall x 39” wide to accommodate personnel and equipment entry and removal.

Value Added Options: Heavy anchorage hardware offer even higher wind load capability for hurricane or storm prone areas; Fire Retardant (FR) resin segments also available.

Head-to-Head Comparison

| Marley Reflex™ Fan Cylinder | Midwest Fan Stacks | |

|---|---|---|

| 1.7% more cooling capacity or 5% less power needed compared to flared cylinder designs of equal height* | Performance | Flared cylinder design of same height is less efficient and needs more horsepower, this translates into increased energy costs (up to $6,535 annually)* |

| Butt flange design is more rigid than lapped flange design | Strength | Lapped flange connection is less rigid which requires additional stiffening bars |

| Smooth interior with no exposed hardware eliminates concerns of fan interference | Fan Interference | Stiffening bars and bolt heads are located within cylinder interior, including the throat area. Impact with fan blade is a concern |

| 10’ tall Reflex shape has larger outlet area for its height allowing for a reduction in overall tower height while meeting performance of taller 14’ height cylinders; shorter height means less surface area for wind to catch, less weight, less hardware, easier to handle in field | Low Profile | A 14’ tall cylinder is needed to match the performance of the Marley Reflex 10’ tall cylinder; taller height means more surface area for wind to catch, more weight, more hardware, harder to handle in field |

| Butt flange design allows bolt and nut access from exterior of cylinder only, and requires less hardware connections, thus reducing labor | Ease of Assembly | Lapped flange requires a person on both the interior and exterior of the cylinder to properly tighten all the hardware and install the stiffening bars; 80% more fastener components required** |

| 35% larger access door area for easier equipment removal** | Access Door (Based on actual test results) | Smaller access door is more difficult to utilize effectively |

*Based on 336” diameter x 10 ft. tall Midwest and Marley fan cylinders operating with 200 HP motor. Marley Reflex cylinder delivers the same air rate at 190 HP as an equivalent height Midwest stack does at 200 HP Annual energy savings of 10 HP is 7.46 kW x $0.10 per kW/hr x 8,760 annual operating hours = $6,535 in energy savings.

**Comparison of Marley Reflex 336” diameter x 10 ft. tall cylinder and Midwest 336” diameter x 10 ft. tall stack (Item # 2810-1-037). Quantity 232 bolts for Marley cylinder vs. 300 bolts + 45 stiffening bars for Midwest stack. 345pieces / 232 pieces = 49% more pieces with Midwest design. NOTE: Midwest also uses 15 segments vs. Marley 14 segments. 75” door opening height x 39” width for Marley cylinder vs. 60” x 36” width at throat for Midwest stack access door. 20.3 square feet / 15.00 square feet = 35% larger access door with Marley design.

Marley® Reflex 14′ Fan Cylinders

Performance:Marley Reflex Fan Cylinders perform up to 2% better in CFM than others to increase cooling tower capacity or require up to 8% less power to deliver equivalent CFM, which can result in up to $10,424 less in annual energy costs.

Strength: Butt flange design requires fewer components to meet industry standards. Spray layup process is the industry standard offering. RTM manufacturing process provides even more strength due to additional fiberglass and elimination of air pocket.

No Hardware in Airstream: All hardware connections are outside the cylinder which eliminate concern for fan interference.

Low Profile: Marley Reflex design allows our 14’ tall cylinders to perform equal to other fan cylinders in the market that are 18’ tall, while offering higher wind load capability and less stress on cooling tower structural frame. Shorter segments also translate to easier handling at jobsite without need for special equipment.

Ease of Assembly: All segment connection hardware can be accessed from fan cylinder exterior due to butt flange design.

Large Access Door: Marley Reflex access door is 6.75’ tall x 6’ wide to accommodate personnel and equipment entry and removal.

Value Added Options: Heavy anchorage hardware offer even higher wind load capability for hurricane or storm prone areas; Fire Retardant (FR) resin segments also available; RTM process in lieu of spray layup upon request.

Head-to-Head Comparison

| Marley Reflex™ Fan Cylinder | Midwest Fan Stacks | |

|---|---|---|

| 2% more cooling capacity or 8% less power needed compared to flared cylinder designs of equal height* | Performance | Flared cylinder design of same height is less efficient and needs more horsepower, this translates into increased energy costs (up to $10,424 annually)* |

| Butt flange design is more rigid than lapped flange design | Strength | Lapped flange connection is less rigid which requires additional stiffening bars |

| Smooth interior with no exposed hardware eliminates concerns of fan interference | Fan Interference | Stiffening bars and bolt heads are located within cylinder interior, including the throat area. Impact with fan blade is a concern |

| 14’ tall Reflex shape has larger outlet area for its height allowing for a reduction in overall tower height while meeting performance of taller 18’ height cylinders; shorter height means less surface area for wind to catch, less weight, less hardware, easier to handle in field | Low Profile | An 18’ tall cylinder is needed to match the performance of the Marley Reflex 14’ tall cylinder; taller height means more surface area for wind to catch, more weight, more hardware, harder to handle in field |

| Butt flange design allows bolt and nut access from exterior of cylinder only, and requires less hardware connections, thus reducing labor | Ease of Assembly | Lapped flange requires a person on both the interior and exterior of the cylinder to properly tighten all the hardware and install the stiffening bars; 80% more fastener components required** |

| 2.3 times larger access door area for easier equipment removal** | Access Door (Based on actual test results) | Smaller access door is more difficult to utilize effectively |

*Based on 336” diameter x 14 ft. tall Midwest and Marley fan cylinders operating with 200 HP motor. Marley Reflex cylinder delivers the same air rate at 184 HP as an equivalent height Midwest stack does at 200 HP. Annual energy savings of 16 HP is 11.9 kW x $0.10 per kW/hr x 8,760 annual operating hours = $10,424 in energy savings.

**Comparison of Marley Reflex 336” diameter x 14 ft. tall cylinder and Midwest 336” diameter x 14 ft. tall stack (Item # 2814-1-200). Quantity 257 bolts for Marley cylinder vs. 405 bolts + 60 stiffening bars for Midwest stack. 465 pieces / 257 pieces = 80% more pieces with Midwest design. NOTE: Midwest also uses 15 segments vs. Marley 14 segments. 6’-9” door opening height x 6’ width for Marley cylinder vs. 5’-8” x 3’ width at throat for Midwest stack access door. 40.5 square feet / 16.98 square feet = 2.38 times larger access door with Marley design.