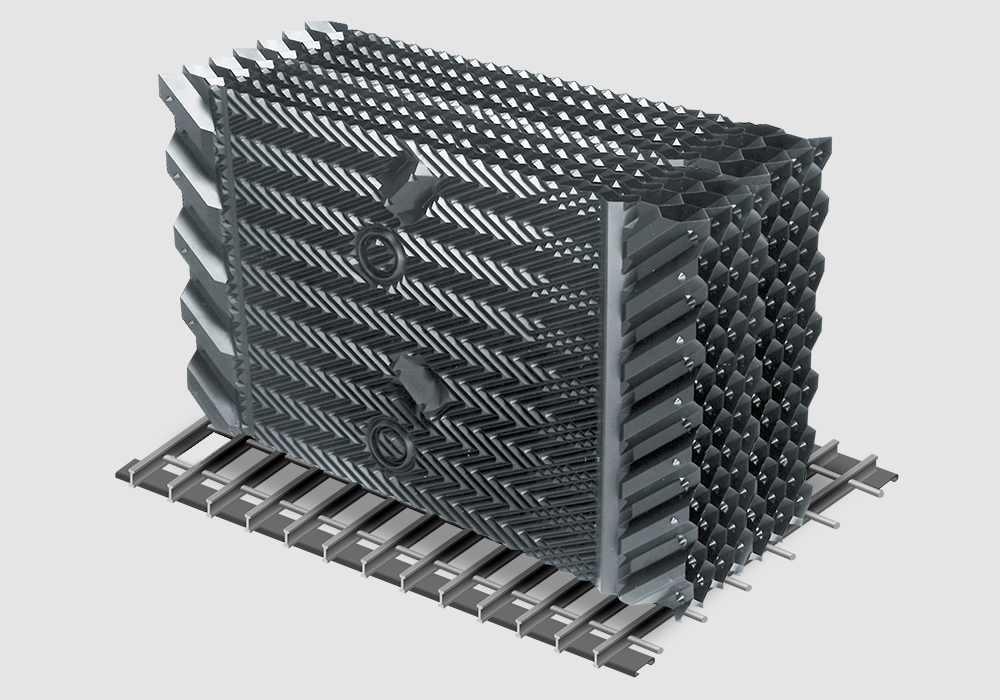

Marley® MBX Fill

Energy Savings

Clogged fill increases cold water temperature, thus increasing demand on a chiller. For example, one degree warmer water can increase chiller energy consumption by 2%.

Lower Installation Cost

Utilizing Marley Bottom Supported (“MBX”) fills can yield 30-40% labor savings compared to replacement with fill sheets.

Drift

With Marley OEM fill replacement, we guarantee drift levels will match original tower

drift performance, reducing impact on neighboring properties.

Ease of Maintenance

Removable fill packs allow for easy cleaning to prolong fill life.

Product Design Knowledge

The PVC formulation used by Marley fill has been specially formulated, tested, and proven to prevent degradation in the harsh conditions of cooling towers*. For example, strong acrylic impact modifiers are used to prevent damage from UV light.

Innovation

We have 23 fill patents, showing our knowledge and dedication of resources to continuously improve our fill products.

Head-to-Head Comparison

| MARLEY® MBX | Brentwood® XF75 | |

|---|---|---|

| Marley MBX fill delivers 9% greater thermal performance compared to Brentwood XF75 fill* | Thermal Performance | Brentwood XF75 fill can reduce thermal performance by increasing cold water temperature up to 9% compared to Marley MBX fill* |

| The greater thermal performance of Marley MBX fill translates directly into lower energy consumption by the chiller in HVAC applications | Energy Savings | Brentwood XF75 fill can result in up to a $2,628 increase in annual energy costs compared to Marley MBX fill due to increased load on the chiller motor** |

| Guaranteed drift levels matching original tower performance, reducing impact on neighboring properties, and prolonging life of the mechanical equipment | Drift | Brentwood XF75 fill exhibited a higher number of drift particles and larger drift particle size*** (Click here to see actual test results) |

| The fill sheets within a Marley MBX fill pack have a standard thickness of 15 mil after forming | Sheet Thickness | Brentwood XF75 fill has options for 8, 10 or 15 mil after forming, so be sure that you understand what they are quoting to get a true cost comparison |

|

Reference: |

||

| * | Based on test results measuring the approach temperature at the SPX CT Development Center. Model NC8306K operating at 50hp and 1746 gallons per minute. HW/CW/WB conditions of 95/85/78 degrees F. |

|

| ** | The 17% reduction in thermal performance yields approximately 1 degree F higher temperature exiting the cooling tower (assuming 95/85/78 degrees F conditions). This can affect the chiller by 2% in lost energy performance due to increased load on the chiller motor. The extra load is required to reject sufficient heat to maintain the same target air temperature. The resulting energy cost increase can be calculated as follows: Chiller motor = 400hp | Lost chiller performance = 2% | 400hp X 2% = 8hp = 6 kilowatts | 6 kilowatts X 8,760 hours per year = 52,560 kW per year | Use average price of electricity in your region to calculate cost per year http://www.eia.gov/electricity/monthly/epm_table_grapher.cfm?t=epmt_5_6_b | Assuming cost of $0.10 per kW hour: Cost = 52,560 X 0.10 = $5,256 annual cost for energy loss of 1 degree F cooling water temperature. |

|

| *** | Based on Drift Particle size sampling at the SPX CT Development Center. |

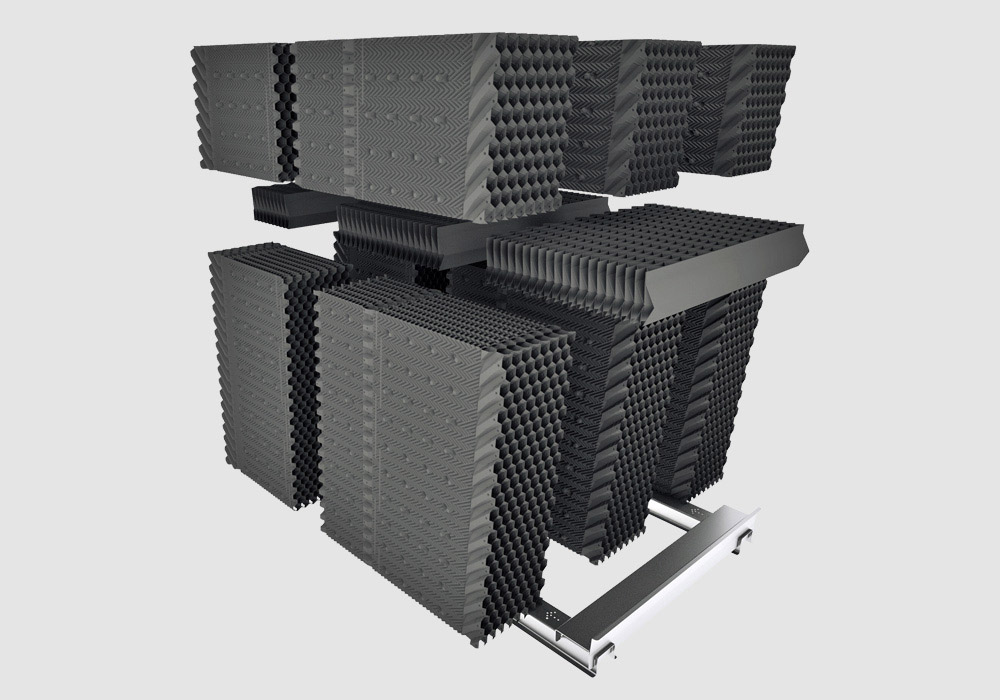

Marley® MBX EZ Fill

Easy To Stock

Contractors can stock packs and easily cut down heights and air travels as needed in the warehouse or in the field. This yields flexibility for install into Marley or other manufacturers’ towers.

Easy Install

2 piece design yields smaller packs for easy job site handling and bottom steel supports require no hardware install.

Lower Installation Cost

Utilizing Marley Bottom Supported (“MBX”) fills can yield 30-40% labor savings compared to replacement with fill sheets.

Drift

With Marley OEM fill replacement, we guarantee drift levels will match original tower drift performance, reducing impact on neighboring properties.

Ease of Maintenance

Removable fill packs allow for easy cleaning to prolong fill life.

Product Design Knowledge

The PVC formulation used by Marley fill has been specially formulated, tested, and proven to prevent degradation in the harsh conditions of cooling towers*. For example, strong acrylic impact modifiers are used to prevent damage from UV light.

Innovation

We have 23 fill patents, showing our knowledge and dedication of resources to continuously improve our fill products.

Head-to-Head Comparison

| MARLEY® MBX EZ | Brentwood® XF75 | |

|---|---|---|

| Marley MBX EZ can be field modified easily to the correct pack height and the air travel configuration needed for either Marley or other manufacturers’ towers. | Easy To Stock | Brentwood XF75 packs do not offer the flexibility of simply cutting the louver pack to change air travel dimensions. |

| Marley MBX EZ comes in 2 pieces for 4.5 and 5 feet air travel dimensions to maintain peak performance and fouling resistance. | Easy Install | Brentwood XF75 requires 3 pieces for air travel dimensions greater than 4 feet, creating another pack interface that may impact performance and fouling. |

| Guaranteed drift levels matching original tower performance, reducing impact on neighboring properties, and prolonging life of the mechanical equipment | Drift | Brentwood XF75 fill exhibited a higher number of drift particles and larger drift particle size* (Click here to see actual test results) |

| The fill sheets within a Marley MBX fill pack have a standard thickness of 15 mil after forming | Sheet Thickness | Brentwood XF75 fill has options for 8, 10 or 15 mil after forming, so be sure that you understand what they are quoting to get a true cost comparison |

|

Reference: |

||

| * | Based on Drift Particle size sampling at the SPX CT Development Center. |